The lathe works by rotating the work piece on its axis to allow, sanding, knurling, drilling, facing or turning with tools to create the desired shape.

Lathes are used by woodturners and many woodworkers to produce some very creative projects. The lathe has its origins with the ancient Egyptians where a two person lathe was developed. One person would turn the wood with a rope while the other would use a sharp tool to cut it. Aren’t we glad the lathe has evolved to what it is today; we can thank the Industrial Revolution for this.

There are many different types of Lathes on the market being used in a variety of different industries.

Woodworking, Metalworking and Watchmaking are the common industries that rely on lathes.

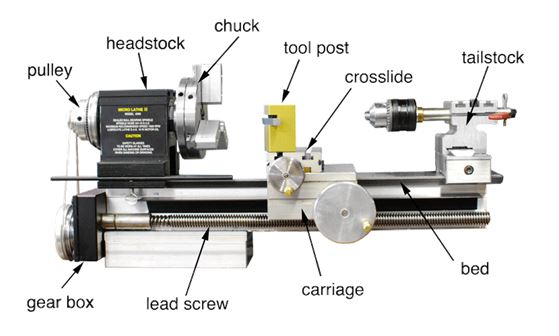

There are some common components that anyone using a lathe needs to know.

• Bed: Usually made of cast iron. Provides a heavy rigid frame on which all the main components are mounted.

• Ways: Inner and outer guide rails that are precision machined parallel to assure accuracy of movement.

• Headstock: mounted in a fixed position on the inner ways, usually at the left end. Using a chuck, it rotates the work.

• Gearbox: inside the headstock, providing multiple speeds with a geometric ratio by moving levers.

• Spindle: Hole through the headstock to which bar stock can be fed, which allows shafts that are up to 2 times the length between lathe centers to be worked on one end at a time.

• Chuck: 3-jaw (self centering) or 4-jaw (independent) to clamp part being machined.

• Chuck: allows the mounting of difficult work pieces that are not round, square or triangular.

• Tailstock: Fits on the inner ways of the bed and can slide towards any position the headstock to fit the length of the work piece. An optional taper turning attachment would be mounted to it.

• Tailstock Quill: Has a Morse taper to hold a lathe center, drill bit or other tool.

• Carriage: Moves on the outer ways. Used for mounting and moving most the cutting tools.

• Cross Slide: Mounted on the traverse slide of the carriage, and uses a hand wheel to feed tools into the work piece.

• Tool Post: To mount tool holders in which the cutting bits are clamped.

• Compound Rest: Mounted to the cross slide, it pivots around the tool post.

• Apron: Attached to the front of the carriage, it has the mechanism and controls for moving the carriage and cross slide.

• Feed Rod: Has a keyway, with two reversing pinion gears, either of which can be meshed with the mating bevel gear to forward or reverse the carriage using a clutch.

• Lead Screw: For cutting threads.

• Split Nut: When closed around the lead screw, the carriage is driven along by direct drive without using a clutch.

• Quick Change Gearbox: Controls the movement of the carriage using levers.

• Steady Rest: Clamped to the lathe ways, it uses adjustable fingers to contact the work piece and align it. Can be used in place of tailstock or in the middle to support long or unstable parts being machined.

• Follow Rest: Bolted to the lathe carriage, it uses adjustable fingers to bear against the work piece opposite the cutting tool to prevent deflection.

We're a premium dealer for Vicmarc lathes. Made in Australia. Check them out here.

Comments (1)

Hello for months I h

Leave a comment