Hello David,

Having watched all of the videos on your site I see that you are a man who does not like paying more than he has to for things, and who believes in the free exchange of ideas and information. In that same spirit I would like to share a couple of cost-saving ideas I have had with you. I am very new to pen turning and I was rather taken aback by the cost of some of the specialist bits of kit. The more so because here in the UK, or 'rip-off' Britain as I prefer to call it, things seem to cost more than anywhere else on the planet.

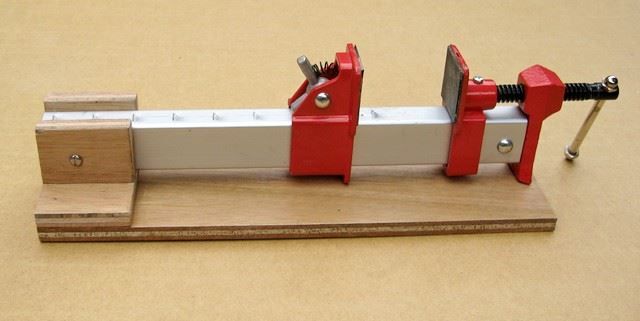

Pen Assembly Press

This is a good example to start with. You have one for sale at 40 Aussie dollars. Over here they range from 35-42 pounds, that is AUD $50-65. If I imported your press it would have 20% Value Added Tax lobbed on which means I could buy one in the UK for more or less the same price. You wonder why us pommies are always whingeing !!!

I have only turned three pens so far and have assembled them using my very ancient and clunky bench vice. There is a fair bit of sideways play in the jaws and I was afraid that sooner or later a brass tube would get cracked so I looked around for something else that would do the job.

I thought a sash cramp would be suitable and I found a budget aluminium one 815mm long for £9.30 (say AUD $15). I glued some plastic to the jaws (I thought this would be a bit kinder on the pen parts than metal) and cut it down to a more manageable length and it works just fine with very close control on pressing the parts together. I mounted it on the plywood base so that I could clamp it to the bench and thus have one hand free for positioning the pen and the other for tightening up.

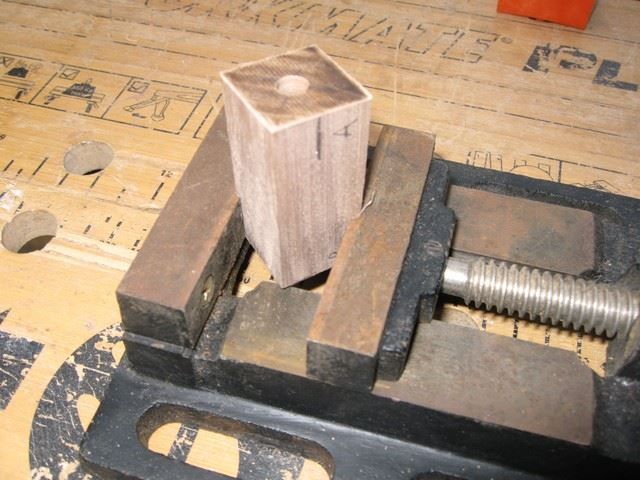

Pen Blank Vice

You have one available for AUD $50, over here what looks like the identical object sells for £46 ($70).

It seemed to me that a common or garden drill vice would do the job (budget versions available here for £9.20, approximately $15) but the standard item lacks a way of ensuring the blank is held vertically except by setting it up with a small square.

I already had a (rather tatty) drill vice so I clamped the jaws firmly shut, put it under the drill press and drilled a 3mm hole right down the joint between the jaws. Perhaps I should have cleaned up the vice a bit before talking the pictures . . .

Please feel free to impart this information to others if you think it has any merit.

Thanks once again for an excellent website and for reasonably priced, good quality products.

Regards,

Alan Currans